DFM is a comprehensive

manufacturing preparation and design output verification before the process of

fabrication.

DFM enables designers to eliminate errors, while ensuring high final product quality, and accurate outputs for the manufacturing processes. DFM is important to address the challenges of the manufacturing process.

How does it work?

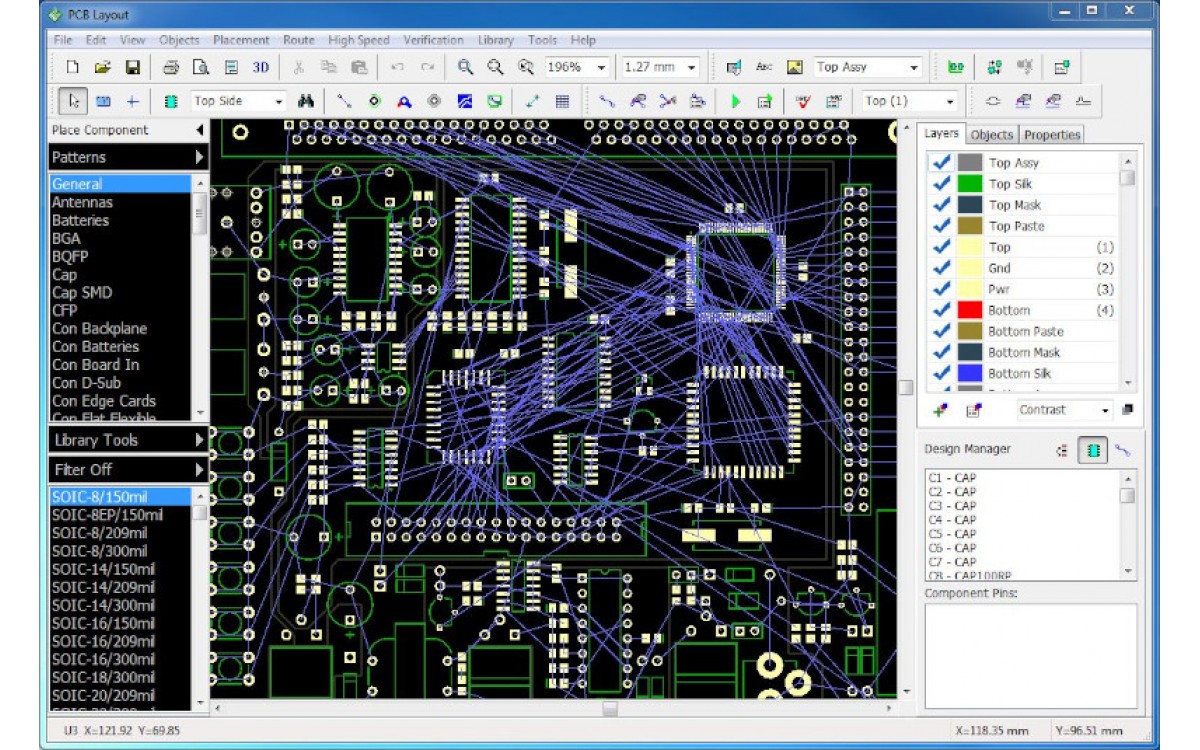

Most of the current PCB design software are

capable to prepare and verify the data prior manufacturing data by paneling up

a single or combination of PCBs with real-time manufacturing DRCs.

Additional fabrication and assembly checks are

applied dynamically based on any manufacturer's specifications. This allows to manufacture

follow to industry standards..

With powerful post-processing functionality,

designers apply the necessary additions and modifications to the design, such

as automatic copper flooding of the complete panel.

Documentation is completed with automatic

drill table generation and various dimensioning options, with access to the

component library to add any additional features to the design.

Once documentation for fabrication, assembly,

and testing is completed, designers generate the output data for manufacturing.

Designers can simulate the panel image for

final verification and import data from manufacturing to compare and analyze

differences between the original data.