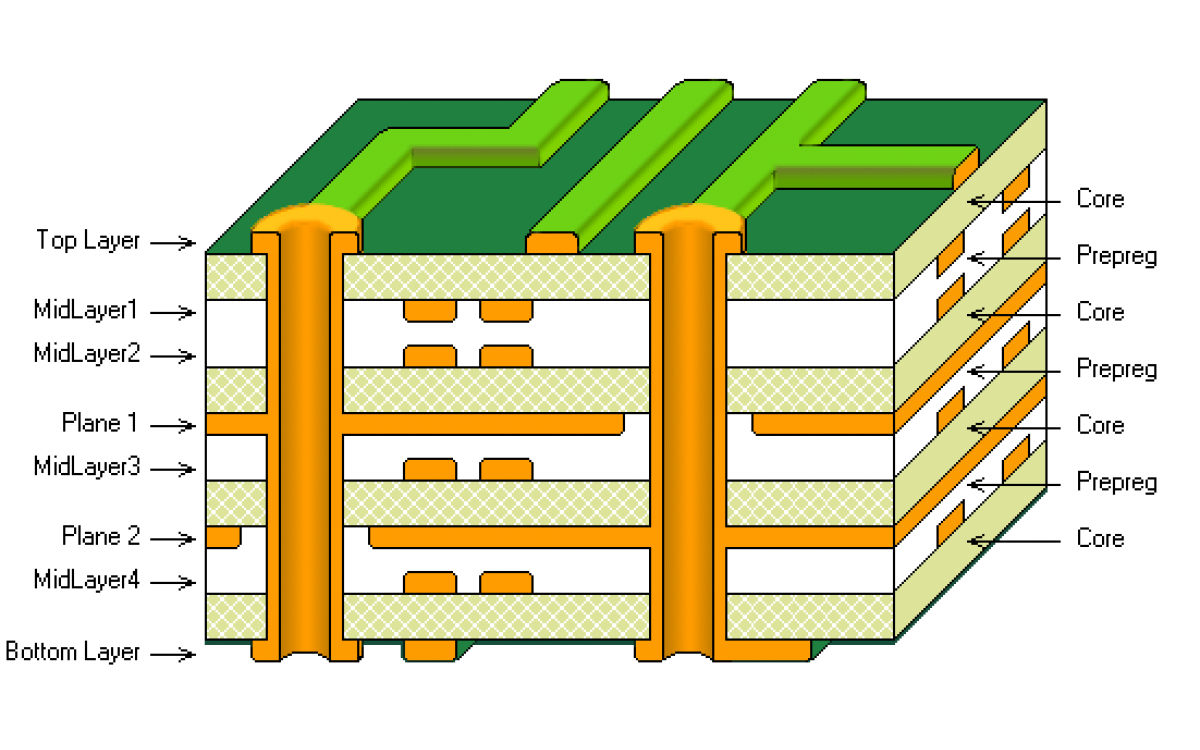

Layers Stack Up

A typical 4 Layer Stackup looks as follows

Signal 1

Ground

Power

Signal 2

Notice that the ground and power are interchangeable. If it

this PCB has many power islands AND there are controlled impedance traces, then

it may be a better idea to keep all the controlled impedance traces on Signal 1

and Ground layer beneath it. If controlled impedance traces refer the power

planes it must not either cross the split power plane junctions. If it is

unavoidable to pass the split power plane junctions, we should place stitching

capacitors.

The four layer trace has one inherent drawback. You can not

keep the power and ground traces tightly coupled for a typical 0.063” thick

PCB.

6 Layer stack up

A 4 layer stack up is pretty much straight forward. A 6 layer

stack up can have a number of variations. We should know the reasons behind

choice of these variations and select the one that suites our requirements. A

typical 6 Layer Stack up looks as follows.

Signal1

Ground

Signal2

Signal3

Power

Signal4

In this stack up the traces on signal2 and signal3 should be

routed in orthogonal fashion to avoid any potential cross talk. Care must be

taken not to route traces in parallel along signal 2 and signal 3.

All 4 signaling layers can refer to at least on power plane.

So all the four signaling layers can have controlled impedance traces. One

drawback of this arrangement is that the power and ground layers are not

adjacent. Adjacent power and ground planes provide inter plane capacitance

which is essential for providing low impedance path for the high frequency

power supply noise. With this in mind some engineers use the following stackup.

Signal1

Signal2

Ground

Power

Signal3

Signal4

The drawback of this stackup ? The Signal 1 and Signal 4 layers

do not refer to the power planes directly. This problem results in inability to

provide a controlled impedance on Signal 1 and Signal 4 layers.

So which stack up do you choose? If your design has very few

high speed signals that need controlled impedance routing, the second stack up

is better choice. You can route all the controlled impedance traces on Signal 2

and Signal 3 layers. The outer layers can be used for normal traces that do not

need controlled impedance.

If however, your design has large number of high speed traces

that need controlled impedance, the second stack up may not provide enough

room. In such case the first stack up is a better choice. If you happen to

choose the first stack up, try to fill the unused spaces on signal layers with

plane flooding. This will provide extra plane capacitance between the power and

ground layers required for the suppressing high frequency power supply noises.

A six layer stack up lacks the number of the power planes. A

typical microprocessor based system will need many small power islands, for

which a single power plane is not sufficient. In this scenario some of the

power islands will have to be on signal2 and/or power plane. If you find the

things hard you may use 8 Layer stack up.

8 Layer stack up

A four layer or a 6 six layer stack have one or other

shortcoming. An 8 layer is the minimum number of layer that sufficiently

addresses all the signal integrity requirements. It does not mean that 4 layers

and 6 layers can not be used. The 4 layer and 8 layer can be and should be used

for lower cost. But they will not fulfill all the signal integrity and EMI

requirements is a dense PCB routing environment.

A typical 8 Layer Stackup looks as follows

Signal1

Ground

Signal2

Power

Ground

Signal3

Power

Signal4

The 8 Layer stack up provides ample routing space for

multiple power islands. In the above typical stack up all signaling layers have

at least one referencing power plane. The power and ground layer in the center

provides good inter plane capacitance. If your system has many power islands

and these power islands are next to the bottom layer, they do not have enough

power to ground capacitance. Also the return path for the high speed signals in

bottom layer (signal4) refer to the power plane which is not adjacent to a

ground plane. For these reasons, some engineers use an alternate stackup as

shown below.

Signal1

Ground

Power

Signal2

Signal3

Ground

Power

Signal4

By keeping the separation between signal2 and signal3 large

we can eliminate any potential crosstalk between signal2 and signal3.

A 4 layer stackup is pretty much straight forward. A 6 layer

stack up can have a number of variations. We should know the reasons behind

choice of these variations and select the one that suites our requirements.

Symmetry and Board Warping

In designing stackup, we should keep the it symmetrical with

respect to the copper and non copper planes. For example of second layer from

the top is a power or ground layer, then the second layer from the bottom

should also be a ground or a power layer. This requirement has to do more with

the mechanical requirement than the electrical requirement. An unsymmetrical

stack up will create warping during any process that applies heat the PCB. A

warped PCB will decrease yield especially if it has BGAs. The heights of the

solder balls will be different in a warped board leading to open conditions and

reducing yield. Keep your stack up symmetrical. If a power plane is partially

filled, fill up the remaining are with copper, even if they are not connected

to a net.

Aliquip veniam delectus, Marfa eiusmod Pinterest in do umami readymade swag. Selfies iPhone Kickstarter, drinking vinegar jean shorts fixie consequat flexitarian four loko.

Lorem ipsum dolor sit amet, justo aliquid reformidans ea vel, vim porro dictas et, ut elit partem invidunt vis. Saepe melius complectitur eum ea

Lorem ipsum dolor sit amet, justo aliquid reformidans ea vel, vim porro dictas et, ut elit partem invidunt vis. Saepe melius complectitur eum ea

Lorem ipsum dolor sit amet, justo aliquid reformidans ea vel, vim porro dictas et, ut elit partem invidunt vis. Saepe melius complectitur eum ea